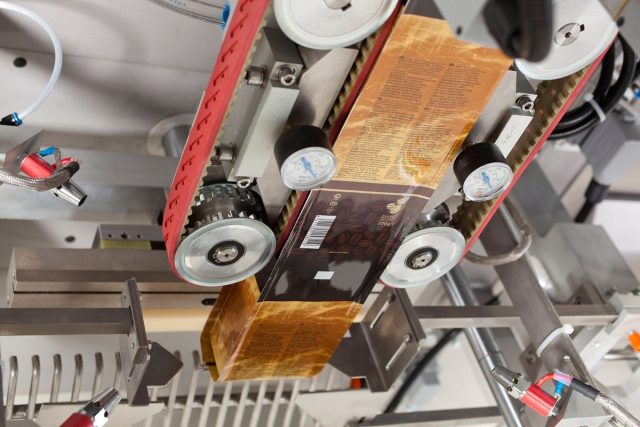

We can’t help but look at the growing popularity of automatic machines that fill and close coffee bags. Precisely because of their impeccably good work, you can enjoy your favorite aroma coffee. If you are wondering why there is so much demand for them, the answer lies in their design. The machines are made in such a way that, thanks to their ease of use, you get the finest finished product. So, whether you are new to this industry or just want to improve your packaging you need to be familiar with these machines completely.

This means that you should know what these machines really are and how they work. If you are interested in reading more about it, you can get some very useful information about these machines in the rest of the text.

Types of machines

These machines are designed with different layouts. This refers to the line and rotational layout. However, you should be interested in a rotating schedule that works on a regular basis thanks to the fantastic characteristics of packaging machines. It is also important to note that there are two popular types, both vertical and horizontal. At woopacking.com you can see first hand what a machine of this type looks like. The main difference between these two types of equipment is that it takes up space. For example, ones that work vertically require less space when it comes to floor area. On the other hand, they need a lot of space when it comes to height.

On the other hand ones with horizontal operations have needs that are reversed by vertical operations. What is interesting is that machines with vertical operations are more popular than other types. The coffee industry simply adores them for several reasons. These are certainly low costs, easy to use, minimal space consumption, high speed and good work technique.

Types of coffee packaging bags

When we talk about the type of packaging bags and its characteristics, we can say the following. Coffee is packaged in different forms. So, it can be coffee beans, ground coffee or instant. In essence, this is completely unimportant, because the machines adapt to different shapes of bags. However, there are several options that are most common when it comes to this process. These are single use packages, flat bottom bags, bag in a package and other options. The essence is in preserving the freshness and the extended shelf life. That is why the coffee industry is trying to meet the standards with the help of machines of exceptional quality.

How does the coffee pouch machine work?

Now that you have learned more about these machines, it is important to get acquainted with the entire packaging process. So, we are talking about the rotational process of packing coffee bags. Of course, a rotary packaging method is used, which implies a focus on an already made bag that is filled with the product. Then the procedure is repeated with each subsequent bag. This happens without pauses between the bags and actually takes place at an exceptional speed. In just one minute, over 150 bags are filled, which is a large number.

Immediately after filling, the bags are moved to various stations that follow the shape of the circle, and that is their distribution. If you are wondering why there are even several stations, it is because each of them has different roles. So, everyone got their task, which they successfully complete. We must not forget another important element, and that is tapes. Mostly it’s up to 4 lanes. Read the details of this procedure below.

Steps

Placing bags

The first thing is to move the already made bags to the place where they are filled with the product, and they are inserted manually, that is, they are placed in front of the machine. They are then transferred to the machine by means of a feed roller. It is important to note that today there are different techniques for inserting bags into the machine and the industry uses the most useful ones. This means that it strives to eliminate any unnecessary effort, while still thinking about the quality of the procedure. For example, a robotic arm is used that uses vacuum suction to handle the bags and place them in the right place where the next step of the process takes place.

Bag recognition

After that, we come to the sensor. The machine must recognize the bag in order to know what to do with it next, and the sensor deserves to be identified. There are all the sensors that control this part of the job if they are not turned on the charging process and closing will not begin. It happens that the bag is placed, but still, the sensors cannot recognize it. In most cases, it is set incorrectly. This means that she will remain in the same position until the next cycle.

However, when the sensors recognize the bag, the vacuum part reacts and moves the bag with the grips. He will lead her to different stations. Grips are very durable elements, but when it comes to slightly heavier bags, an additional bag holder is also used.

Stamping

As we have already said, there are different stations. If something is imprinted or printed, the equipment is placed at the station, which is in charge exclusively for this part of the job. Different printers are used and it depends on the production needs. There are also many embossing options and this applies to date, series…

Filling the bag

The way the bags are filled largely depends on the type of product. For example, there is a difference between liquid bags and powder bags. Then there is a difference in the filling part, because each type of bag requires a different type of filling with a nozzle. The filling part does its job very precisely by taking into account the amount of product that ends up in the bag.

Cooling

Finally, we come to the part where the final steps are taken before the process is concluded. This refers to the strengthening and alignment of the product, and then the bag is forwarded or moved from the packaging machine to another place. It is mostly a space for transportation, and then the last checks take place, such as measurements, etc.

Conclusion:

We hope that we have helped you to get a little deeper into the process of turning an empty bag into a finished product. It is important to note that these machines do not provide any finished product but one with superior aesthetics. This is equally important for business people and consumers.