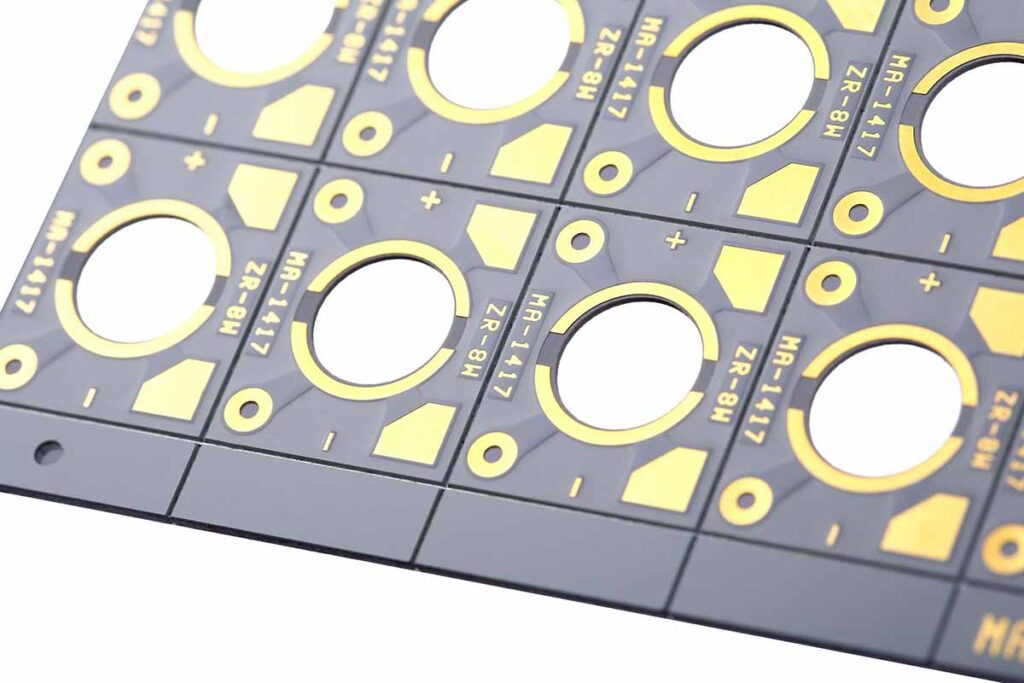

PCBs or printed circuit boards are used to protect and connect components found in electronic devices. Nowadays they are used in almost every industry, starting from medicine up to electrical engineering and device manufacturing.

These boards can be made from a lot of different materials, and here we are going to talk about why you should select aluminum as the main material from which the boards are made.

Structure

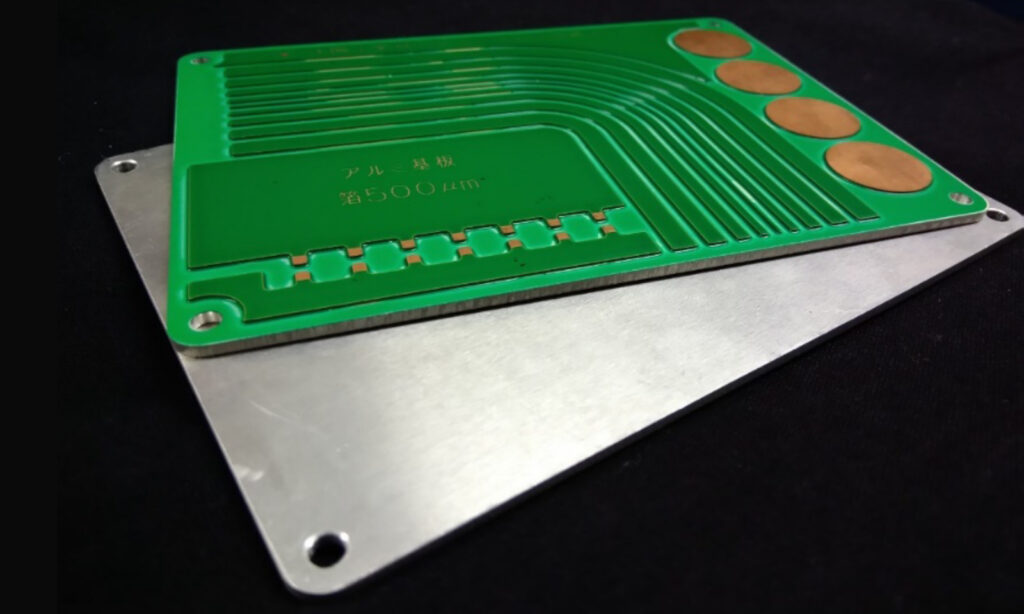

The main structure of Aluminum PCB boards is divided into three main components or layers. The first layer is called the base layer. This is the part where you are able to choose the main material. Here we are going to look at aluminum as the main material, but copper can also be used. The second layer is dielectric and the thickness can vary between 0.08 millimeters or 0.003 inches up to 0.15 millimeters or 0.006 inches. The third layer is also called the circuit layer. It is made of copper foils that can have different thicknesses and weights. The weight usually varies between 28 grams, or 1 oz and 280 grams, or 10 oz.

You should also know that there are modern-day PCBs that have only one conductive layer, but they are not commonly used because they are pretty restrictive. When the designer has to cut them, they may easily break or get damaged. Because of that, the additional two layers we talked about are added to make sure that the end product will not get damaged with time and that will give all the protection needed.

Types

There are three main types of aluminum PCB that are used to protect important components. They include:

- Flexible – these boards offer high levels of insulation, flexibility, and thermal conductivity. With it, different forms can be made, and that cuts the costs for production. It eliminates the need for additional components, including fixtures and connectors.

- Through-hole – as the name suggests, the material is drilled before the production process. After that, a dielectric is added to the hole to make the end product better and more conducive.

- Hybrid – this type is used to improve the durability and lower the costs of the PCB. It is mostly used in RF applications.

Lightweight

One of the biggest reasons why people choose these boards is because they are extremely light. As you already know, the aluminum itself is one of the lightest metals, and because of that, it is the perfect material to make the boards of.

Despite the low weight, this metal offers products additional protection, resilience, and strength.

Durable

Even though this material is not as sturdy when compared to others, it is actually really durable and long-lasting. In case you accidentally drop it, it will not break and studies show that it is pretty hard to damage as well.

It provides better protection and strength to products that are put in these boards and you’d need a lot of force to be able to even scratch it.

Inexpensive

If you are looking for a material that is easy to use, offers a lot of protection, is durable, and comes at low costs, then you should create the printed circuit boards from aluminum.

The reason for this is that it is easy to find, mine, and refine. According to PCBOnline, the combination of the material being easy to find, extract, and construct makes the manufacturing process faster, thus making the end product cheaper.

Simple and easy to use

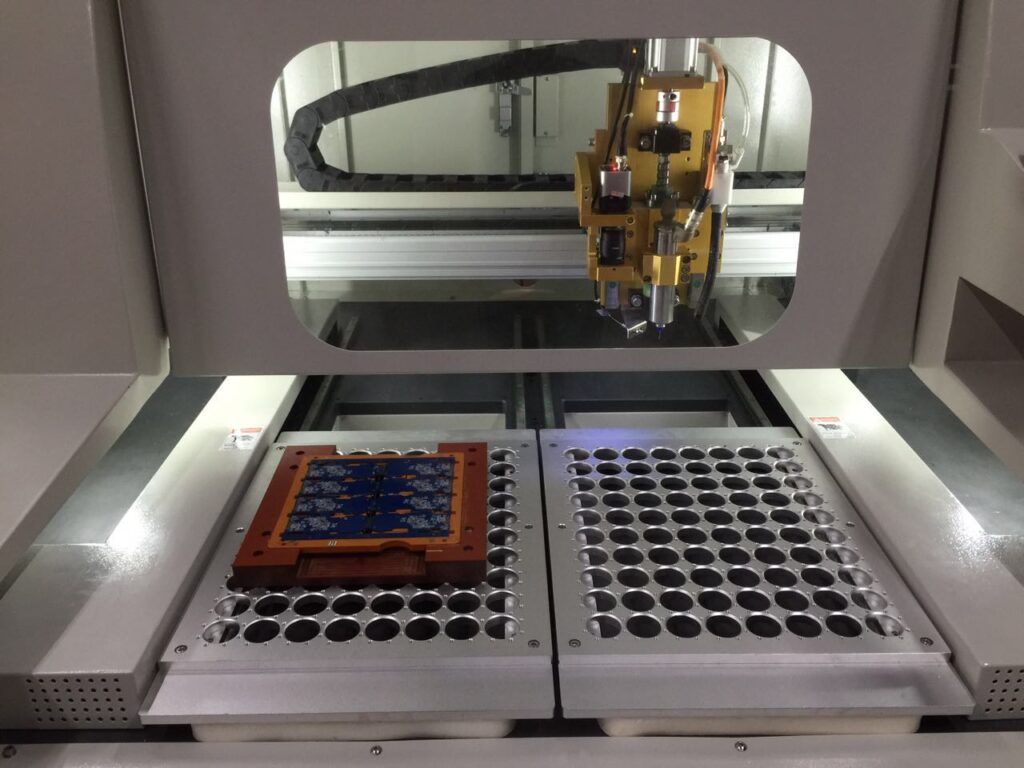

Many manufacturers are wondering if assembling these boards will take a lot of time. The reality is, they are extremely fast and easy to create and you won’t need to spend a lot of time and energy to assemble them. Compared to similar materials, aluminum is easier to work with, and with that, easiest to make the printed circuit boards.

Heat

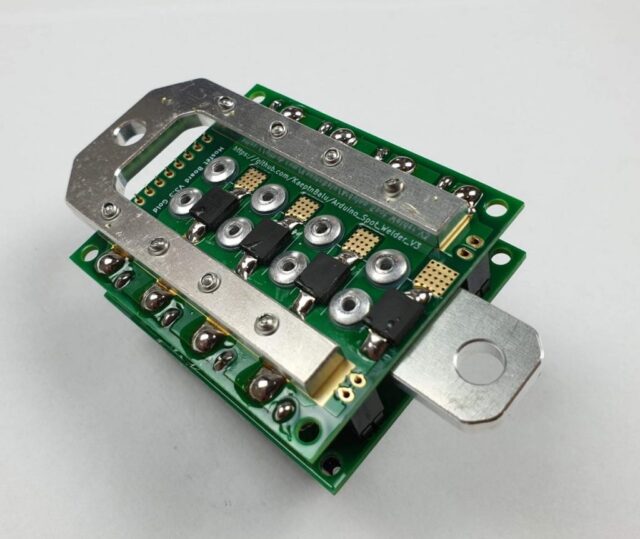

We all know that the reason why we’re using Aluminum PCBs is to protect the components of the products. When they get exposed to high temperatures, they can get damaged easily.

Because of that, scientists had to find a way to make the heat dissipate and protect the inside of the product. Aluminum has shown to be the perfect material for that. It has the ability to take the heat from the components and with that protect them.

When a printed circuit board is not used, the product gets heated quickly, and everything in the inside gets damage right away.

Environmentally friendly

Since you won’t need to use a lot of power to create the Aluminum PCB, you will be able to conserve energy. So, if you are looking for a material that is good for the planet, then you should opt for aluminum.

Another important thing to consider is if the material is recyclable or not. These boards are non-toxic and they can easily be recycled, which adds to the environmentally friendly factor.

Products

There are a lot of different products that are protected by the printed circuit boards, and you were probably not aware of most of them. For example, computers and car motors all use aluminum PCB as well as all the lamps and lanterns. Here are some of the other products that need to have printed circuit boards:

- All kinds of amplifiers

- Most electronic equipment

- Power supply devices

- Audio equipment

- CPU boards

- Landscape lights

- Medical lights

- Signaling equipment

These are some of the most important things you should know about aluminum printed circuit boards. They have a wide variety of uses, and nowadays most companies choose them before any other material. You can find them in most modern-day appliances, and since people began using them, they managed to improve the durability of the components in almost every electrical product.

The costs are lower and the performance is higher, so with all of this information, you should be able to make the right choice. If you are still not sure if this is the right material for your PCB, you can always get an expert’s advice and listen to what they have to tell you about this material compared to others.